The road to nirvana |

|

My journey into Photography, Horology, and Audiophilia |

DIY Speakers

Bass reflex cabinet for the Cube Audio F8 Magus

July 19, 2023

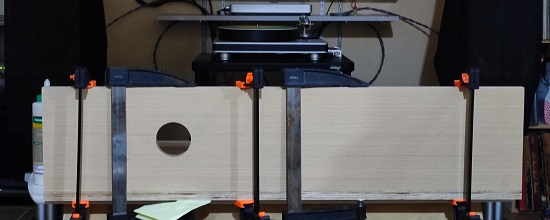

While waiting for the Cube Audio F8 Magus to arrive, I decided to document how I built the bass reflex cabinet designed for it.

The trigger

There is a Facebook Marketplace listing for veneered marine ply and during the course of inquiry with the representative of Heavy Duty Depot in Taytay Rizal, she surprised me that they do cutting services. Using the superb Cutlist Evo online service, I generated a cutlist from the specifications found in the Cube Audio website and asked the representative to see if it's possible. To my delight, she came back swiftly and told me they can do it. I haven't experienced "it feels like heaven" feeling for a very long time until now as cutting a 4' x 8' plyboard is something I can't do.

I paid 5,500 for the 4' x 8' x 18mm veneered marine ply (Moon Oak), cutting service, and delivery fee. I can't contain my excitement that the entire process took just the next day including delivery.

Happiness When the boards arrived, I immediately examined the quality of the cuts and they're satisfactory with no chipping on the edges of the veneer on both sides. The dimensional accuracy as measured reveals a consistent -1mm

offset (perhaps due to the cutting method), i.e., 950mm turned out

949mm and that is fine with me.

The dimensional accuracy as measured reveals a consistent -1mm

offset (perhaps due to the cutting method), i.e., 950mm turned out

949mm and that is fine with me.

Lack of tools

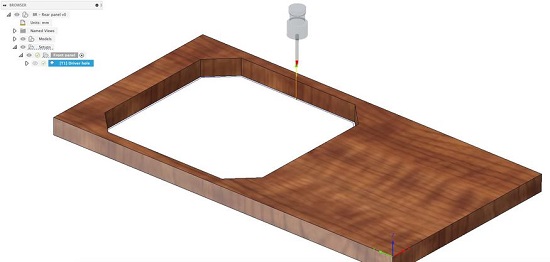

I don't have proper tools nor skills, to cut the holes for the

drivers and ports. In this instance, I'm leveraging on my basic

knowledge of Fusion 360 to create the milling GCODE for my Snapmaker

A250.

Lack of tools

I don't have proper tools nor skills, to cut the holes for the

drivers and ports. In this instance, I'm leveraging on my basic

knowledge of Fusion 360 to create the milling GCODE for my Snapmaker

A250.

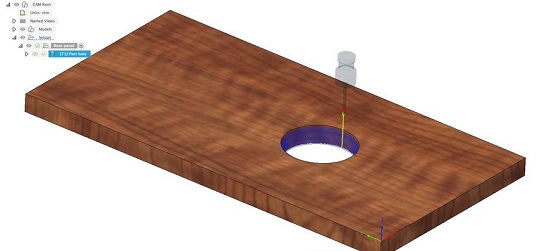

Snapmaker A250 you say? Isn't that too small with a bed size of 235mm

x 250mm? Yes, but the dimensions of the cuts and the width of the

front and rear stock will fit the Snapmaker 250 bed. I created a

contraption out of my Black & Decker workbench to support the end of

the stock and minimize the stress on the bed.

Snapmaker A250 you say? Isn't that too small with a bed size of 235mm

x 250mm? Yes, but the dimensions of the cuts and the width of the

front and rear stock will fit the Snapmaker 250 bed. I created a

contraption out of my Black & Decker workbench to support the end of

the stock and minimize the stress on the bed.

The stock was secured on the bed using double adhesive tape. After a

few hours, I am pleased with the result of the milling on the front

and rear boards.

The stock was secured on the bed using double adhesive tape. After a

few hours, I am pleased with the result of the milling on the front

and rear boards.

The success I had was not replicated on the second set of stock as

the double adhesive tapes failed and caused a mishap during the

milling. Thankfully, I returned on time to check the job and stop

the operation.

The success I had was not replicated on the second set of stock as

the double adhesive tapes failed and caused a mishap during the

milling. Thankfully, I returned on time to check the job and stop

the operation.

To have a more secure bond between the bed and the stock, I applied

a layer of masking tape, then double adhesive tape, and "super glue"

on both the bed and stock contact surfaces. The enhanced adhesion

was more than enough for the jobs to complete without issues, which

allowed me to salvage the front panel.

To have a more secure bond between the bed and the stock, I applied

a layer of masking tape, then double adhesive tape, and "super glue"

on both the bed and stock contact surfaces. The enhanced adhesion

was more than enough for the jobs to complete without issues, which

allowed me to salvage the front panel.

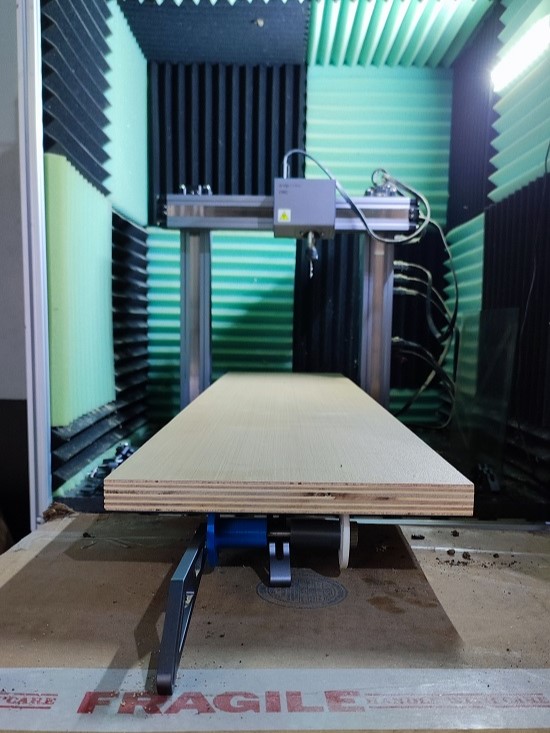

With the front panel and rear panel holes completed, it's now time

to do some glueing. The plan was to glue the back panel to the left

side panel first, followed by the front panel, then the top and

bottom. The right panel goes last so that I have room to attach the

acoustic foams.

With the front panel and rear panel holes completed, it's now time

to do some glueing. The plan was to glue the back panel to the left

side panel first, followed by the front panel, then the top and

bottom. The right panel goes last so that I have room to attach the

acoustic foams.

Thankfully, I was gifted a long table from a distant past that now

serves an important purpose. I made sure that the panels are

perfectly square before clamping.

Those orange clamps failed one by one so before the 7-day return

period ends I had them exchanged to these instead.

Thankfully, I was gifted a long table from a distant past that now

serves an important purpose. I made sure that the panels are

perfectly square before clamping.

Those orange clamps failed one by one so before the 7-day return

period ends I had them exchanged to these instead.

After 48 hours, I started cutting and test fitting the acoustic

foam. Based on the specifications, the acoustic foam is applied only

to the top and rear panels but I also intend to line up the side

panels with the polyester fiber.

After 48 hours, I started cutting and test fitting the acoustic

foam. Based on the specifications, the acoustic foam is applied only

to the top and rear panels but I also intend to line up the side

panels with the polyester fiber.

The acoustic foam is secured to the panels using double adhesive

tape and I'm confident on the strength of the adhesion. The

polyester fiber was lined up with masking tape first, then double

adhesive tape for a secure bond onto the side panels. In case the

measurements don't look good, I can easily remove the polyester fill

on the side panels.

The polyester fiber fill can be easily trimmed using a steel ruler

and sharp cutter.

The acoustic foam is secured to the panels using double adhesive

tape and I'm confident on the strength of the adhesion. The

polyester fiber was lined up with masking tape first, then double

adhesive tape for a secure bond onto the side panels. In case the

measurements don't look good, I can easily remove the polyester fill

on the side panels.

The polyester fiber fill can be easily trimmed using a steel ruler

and sharp cutter.

The round file was used to enlarge the port hole just a little bit

for that perfect fit of the 3D-printed port tube.

The round file was used to enlarge the port hole just a little bit

for that perfect fit of the 3D-printed port tube.

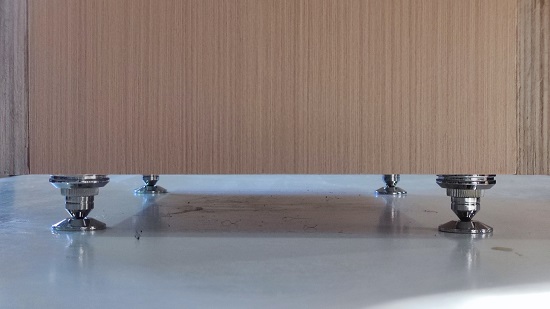

I am pleased with the quality of the binding posts and adjustable

spiked feet. Instead of the suggested horizontally aligned binding

posts, I decided to make them vertically aligned just like my

Scansonic MB3.5B.

I am pleased with the quality of the binding posts and adjustable

spiked feet. Instead of the suggested horizontally aligned binding

posts, I decided to make them vertically aligned just like my

Scansonic MB3.5B.

After the internal wires were screwed to the binding posts, it's

time to address the remaining part I am struggling with...

After the internal wires were screwed to the binding posts, it's

time to address the remaining part I am struggling with...

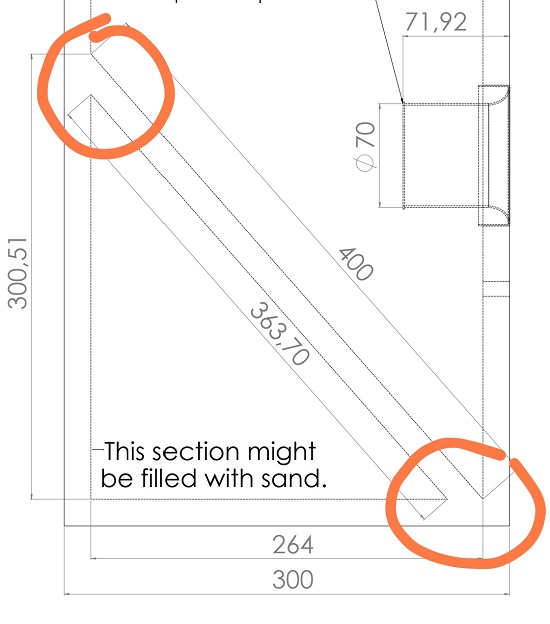

There was no angle specification so I had to physically mark this

piece for cutting. Initially, I thought of buying a cheap tabletop

table saw to accomplish the required edge angles. But they're not

simply 45° and while the angles can be derived and cut using a table

saw, I am not confident doing it. The next option is to use a

router, which since purchase I haven't even broken the seal. Make

the edge cut and file the stock like crazy to achive the required

angle. The last option is to use a jigsaw. However, I remember that

I never got a straight cut using it since I bought the tool. In the

end, I told myself "screw it" and simply used the double edged saw

and I was surprised by the results! It was actually reasonably

straight!

There was no angle specification so I had to physically mark this

piece for cutting. Initially, I thought of buying a cheap tabletop

table saw to accomplish the required edge angles. But they're not

simply 45° and while the angles can be derived and cut using a table

saw, I am not confident doing it. The next option is to use a

router, which since purchase I haven't even broken the seal. Make

the edge cut and file the stock like crazy to achive the required

angle. The last option is to use a jigsaw. However, I remember that

I never got a straight cut using it since I bought the tool. In the

end, I told myself "screw it" and simply used the double edged saw

and I was surprised by the results! It was actually reasonably

straight!

I still filed the edges to minimize the gaps against the front and

bottom panels. With both the pieces glued in place according to

specifications, it is time to fit and glue the side panels and let them cure for another

48 hours. Finally, the adjustable spiked feet were attached to the

bottom using the supplied round double adhesive tapes.

I still filed the edges to minimize the gaps against the front and

bottom panels. With both the pieces glued in place according to

specifications, it is time to fit and glue the side panels and let them cure for another

48 hours. Finally, the adjustable spiked feet were attached to the

bottom using the supplied round double adhesive tapes.

So there, the cabinet has been completed and now I await the arrival

of the drivers from Poland. Here they are beside the Scansonic

MB3.5B.

So there, the cabinet has been completed and now I await the arrival

of the drivers from Poland. Here they are beside the Scansonic

MB3.5B.

I applied a single coat of Odie's Oil using the applicator and

towels which made the laminated wood shinier, but that's about it. I

didn't expect some magic to happen because of the laminate but I'm

pleased nevertheless.

Sound check

So how does it sound? How does it measure compared to its big

brother F10 Neo and my other speakers?

On to the listening experience...

Materials used

Here's the list of materials to complete this project.

I applied a single coat of Odie's Oil using the applicator and

towels which made the laminated wood shinier, but that's about it. I

didn't expect some magic to happen because of the laminate but I'm

pleased nevertheless.

Sound check

So how does it sound? How does it measure compared to its big

brother F10 Neo and my other speakers?

On to the listening experience...

Materials used

Here's the list of materials to complete this project.- Cube Audio F8 Magus drivers

- 18mm marine ply

- Heavy duty binding posts

- Old IXOS 6006 Gamma Geometry speaker wires

- Adjustable spiked feet and plate

- 3D printed 70mm diameter port pipe

- Acoustic foam 5cm thickness

- Polyester fiber fill ½" thickness

- Titebond III wood glue

- Odie's Oil Starter Kit

- Tapes. Masking tape, double adhesive tape.

- Snapmaker 2 A250 3-in-1 modular system

- Cetus 3D Mk III 3D printer (discontinued)

- Various clamps

- Double edged saw for the angled edge cuts

- Round file, wide flat file

- Sanding blocks