The road to nirvana |

|

My journey into Photography, Horology, and Audiophilia |

Dealing with Cetus 3D nozzle clog

July 2, 2019

My Cetus3D MK3 has been printing without issues since I assembled it and I was wondering why many users have been posting about clogging problems online. I wasn't able to relate, until one day out of the blue, my 0.4 nozzle got clogged.

I simply changed to another filament after about 2 days of resting the MK3 and it was indeed a frustrating experience, so I feel you guys!

In the end, I was able to develop a process that works for me to combat this clogging issue. But first, we have to know the anatomy of the Cetus3D nozzle.

The anatomy of the Cetus3D nozzle

<photo>

As shown in the photo, the nozzle assembly is made up of three main components. From right to left, the brass nozzle, the throat, and the PTFE tube (inside the throat).

A nozzle clogged

I found out that clog can happen inside the throat and/or inside the nozzle. Removing a trapped filament inside the throat is easy, just push it out with a properly sized tool.

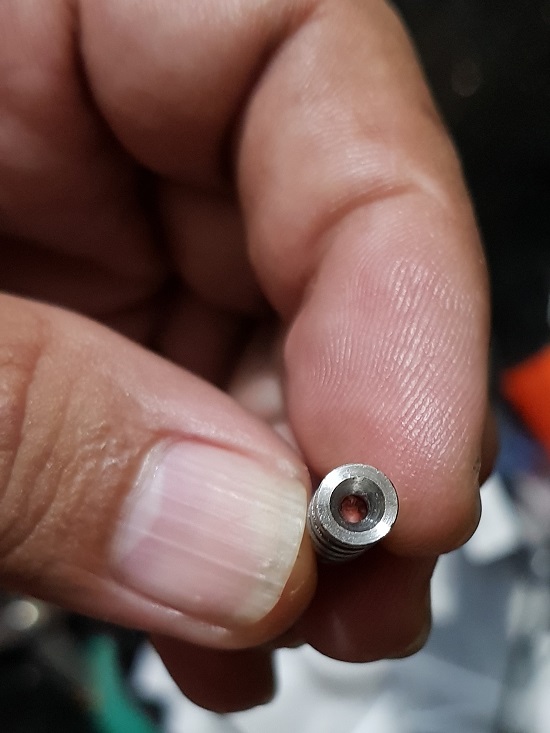

If the blockage is inside the nozzle as in the following photo, the procedure isn't as trivial.

In order to address this clog, the procedure will depend if the nozzle is 0.2 or the 0.4/0.6.

Dealing with it

With a 0.2 nozzle where the tool will not fit the nozzle opening, here's what I do.

- insert the nozzle less the throat, into the heat block. Do an extrude or withdraw to heat up the nozzle at the maximum temperature rating for the filament that's jammed.

- Push the tool through the top of the nozzle until it hits the bottom and leave it in that position.

- Stop extrude/withdraw to get the temperature down and when it hits about 40° C less, pull the tool and filament will cling to it.

- Remove the stuck filament from the tool.

- Repeat the process.

With the 0.4/0.6 nozzles where the tool fits the opening, I insert the tool from the bottom and most of the time, the filament will start to flow. In case of severe blockage, the procedure for 0.2 nozzle works all the time.

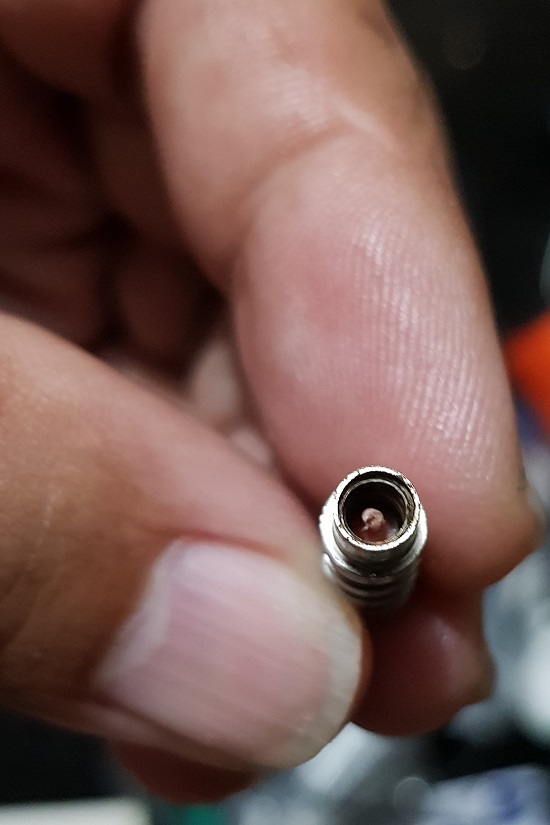

Here's a sample of the debris I was able to pull out of the 0.2 nozzle.

To further minimize the occurence of the clog happening, I no longer let a filament inserted into the nozzle for prolonged period, like 2 days or more. If I will not use the Cetus, I'd do a withdraw and keep the filament inside my eSUN eBOX and heat it before use.

Should the PTFE tube inside the throat deteriorate beyond use, I have on hand replacement tubes. I got them from an online reseller and it's 3mm OD and 2mm ID. I cut them to proper length using my 3D printed filament cutting guide modelled by Luke Hatfield, it's in Thingiverse.